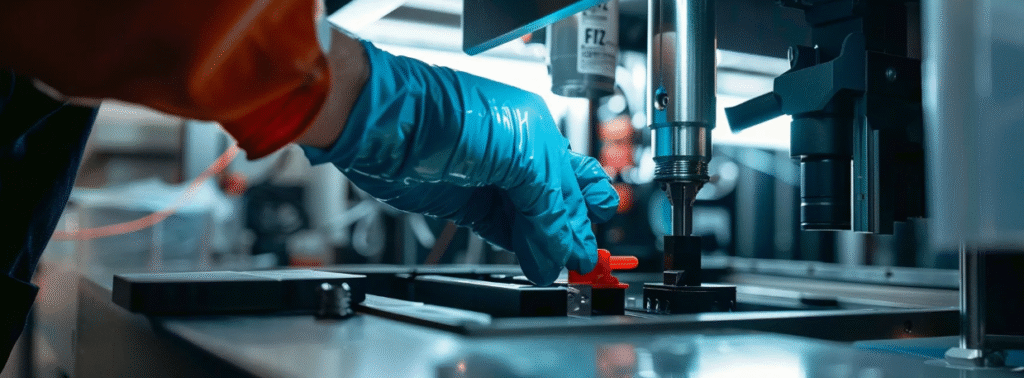

In the realm of industrial applications, securing components and protecting equipment during manufacturing and transportation is crucial. Taper plastic plugs offer an essential solution for a myriad of uses, including sealing, protection from contaminants, and even as masking aids during finishing processes. Recognized for their versatility and efficiency, these inconspicuous components play a pivotal role in the day-to-day operations of various industries. Keep reading to unlock the full potential of these industrial necessities.

Key Features and Advantages of Taper Plastic Plugs in Manufacturing

The chief benefit of using a taper plastic plug in manufacturing is its versatility. Capable of fitting a broad range of hole sizes, these plugs reduce the need for a large inventory of specific sizes, simplifying stock management. This adaptable design minimizes waste by allowing one plug to serve multiple purposes, thereby enhancing cost-efficiency.

Durability is another significant feature, with plugs typically made from materials like high-density polyethylene or vinyl, which are both sturdy and flexible. This ensures that the plugs can withstand harsh industrial environments, including exposure to chemicals and extreme temperatures, without compromising their sealing capabilities.

Furthermore, the design of these plugs often includes ergonomic considerations, such as flanges or pull tabs for easy removal. This thoughtful addition reduces the risk of workplace injuries, which can arise from the repetitive motion of installing and removing traditional plug designs.

Application Spectrum: How Taper Plastic Plugs Are Used Across Industries

The application of tapered plastic plugs stretches across a wide spectrum of industries due to their adaptability. In automotive manufacturing, they’re used to protect critical engine and chassis components from debris and moisture, ensuring that vehicles meet stringent performance standards. They also serve as maskants in surface finishing processes, protecting areas from paint or coating applications.

In oil and gas operations, where sealing and protection from contaminants are of paramount importance, taper plastic plugs prove indispensable. They shield sensitive equipment from the invasion of foreign substances, thus preserving functionality and prolonging lifespan. These plugs also play a role in hydraulic systems, maintaining system integrity by capping openings during maintenance or part replacement.

Electronics and aerospace sectors gain from the precision and reliability of these plugs. They ensure that during transportation and installation, critical components remain unaffected by dust and other particulates. The electrical industry, known for its stringent safety and compliance standards, utilizes these plugs to protect wiring and circuitry during fabrication.

Materials and Design Considerations for Taper Plastic Plugs

When it comes to materials for taper plastic plugs, manufacturers must consider the application’s specific requirements, such as temperature resistance, chemical compatibility, and physical durability. Common materials include polyethylene for general-purpose plugs and silicone or EPDM rubber for high-temperature applications. Selecting the appropriate material is critical to ensuring the plug performs as intended in the given environment.

Design is another fundamental factor in the effectiveness of a tapered plastic plug. The taper should be designed to accommodate a range of hole diameters while still providing a secure fit. Dimensions such as the plug’s overall length and the taper’s angle can significantly affect performance, particularly in preventing leaks or accidental dislodging.

Additional design features may include a relief hole at the end of the plug to allow for air pressure equalization, which prevents the plug from becoming dislodged in applications involving pressure changes. Reinforcing ribs or extra-thick walls can provide increased strength where needed, adding to the plug’s overall durability and life span.

See also: How Technology Is Driving Innovation in Food Production

Best Practices for Selecting and Implementing Taper Plastic Plugs in Industrial Settings

Selecting the right taper plastic plug for a specific industrial application involves consideration of the environment in which it will be used, the materials involved, and the physical demands of the task. It begins with a clear understanding of the parameters, such as diameter range, temperature conditions, and exposure to chemicals or abrasives.

It is also prudent to consider the longevity of the application. For long-term solutions, selecting higher-quality materials that can withstand repeated use or extreme conditions is crucial. Conversely, for temporary uses where cost might be a bigger factor, more economical materials might suffice.

Overall, taper plastic plugs stand as a testament to the power of simple yet effective industrial solutions. Their diverse applications and ability to conform to various settings make them a staple in protecting, sealing, and improving manufacturing operations. By choosing the right plugs and employing them strategically, companies can ensure the durability and integrity of their products, contributing to higher quality standards and operational excellence.